Start small, Scale smart

Established in 2012, Moldwelt has grown into an high-precision tool specialist for plastic injection. Over the years, we have provided robust tooling solutions for several market segments, including automotive, food and industrial packaging, flower pots, and home appliances.

Our in-house injection molding capabilities ensures flawless tool validation and allows us to produce low volume batchs with unmatched efficiency and quality control, ensuring a seamless transition to full production.

Starting a new product? Our prototypes and bridge tools minimize risk and get you to market quickly.

Ready for scale? We will provide you the right tool with the right technology.

Don’t be the same.

Be better.

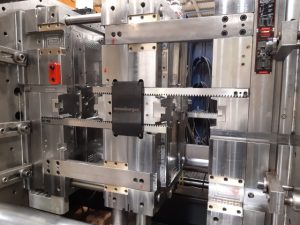

Rapid Tooling, Serious Endurance

Bridge tooling is your accelerator, not a compromise. Manufactured from aluminum or soft steel, it’s the strategic shortcut that eliminates the gap between 3d printing and mass manufacturing.

It empowers you to validate market demand with genuine, production-grade parts today, all while retaining the flexibility to fine-tune your design without committing to the huge cost of full serial molds. Go to market faster, smarter, and cheaper.

Our bridge tools give you the ultimate competitive edge: the speed of a prototype with the endurance of a production mold. We can have your custom tool ready under 5 weeks, yet our rigorous engineering ensures it’s built for the long haul—capable of running up to 40,000 high-quality shots.

Injection molds

With over 400 tools under our belt, at Moldwelt we offer proven tooling expertise. We are prepared to deliver robust serial tools up to 10 tons, ensuring high-volume and extended tool life-time, for your largest projects.

Extremely accurate work

[…]

Precision Injection Molding; Up to 350 Tons

Our injection molding platform scales from rigorous tool trials straight into low-volume production, up to 350 tons of clamping force and 900 cm3 shot capacity. Engineered for versatility, we expertly process everything from commodity polymers to demanding high-performance materials—including heavily reinforced with glass and carbon fiber—delivering the power and precision your most challenging components demand.

Speed and Efficiency

Your project on time

Moldwelt guarantees its customers reliability on time,

maintaining the highest quality in all situations

Quality Policy

MOLDWELT to carry out its mission, bets on a Quality Policy based on the following principles:

- Comply with all applicable legislation and legal requirements, standards and regulations;

- Strict fulfillment of the requirements and specifications of Customers, always with a view to their Total Satisfaction;

- Establish healthy Partnership and Trust relationships with Clients, Suppliers, Employees, as Relevant Stakeholders;

- Develop an organizational culture focused on Continuous Improvement, Risk and Opportunities Management.

Company values

We assume as fundamental values in our company: accuracy, honesty and a sense of responsibility. We recognize and value professional ethics and respect in the relationships between our Clients and Suppliers, the spirit of teamwork, the dynamism and initiative of our Human Capital, in the search for continuous improvement of our Company.

MOLDWELT //CONTACTS

Rua da Embra 2A, 2430-108 – Marinha Grande – Portugal

T. +351 244 235 987 | E. geral@moldwelt.pt

![Automóvel [Interior]](http://moldwelt.pt/wp-content/uploads/2015/10/Auto-P002.jpg)

![Doméstico [Cozinha] Bi-material](http://moldwelt.pt/wp-content/uploads/2015/10/MDW-P011.jpg)